Results 17,841 to 17,850 of 20602

Thread: What are you working on?

-

02-16-2020, 07:27 AM #17841Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

If you keep the speed low and be mindful of the direction of turn, and pay close attention, a Dremel can be very useful. They do make scotchbrite wheels for these. I imagine they are not a big spend either.

It's not what you know, it's who you take fishing!

-

02-16-2020, 12:35 PM #17842Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,819

Thanked: 563

These are what I bought. They work well as long as you are careful about pressure, speed and direction of rotation. I use the hand held flex shaft attachment - it gives greater control.

https://www.amazon.ca/Yasumai-Abrasi...s%2C245&sr=8-2David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

The Following 3 Users Say Thank You to DZEC For This Useful Post:

BobH (02-19-2020), ppetresen (02-16-2020), ScoutHikerDad (02-16-2020)

-

02-16-2020, 01:28 PM #17843

I like the green ones.

I get mine off a guy at our local flea market, during the summer. 36 in a box, and a lot cheaper than the ones dremmel sells.

I found that with the dremmel, using a circular motion, leaves the best finish. I typically tape the blade with scotch tape, and remove the tape from the areas I want to finish.Last edited by outback; 02-16-2020 at 01:32 PM.

Mike

-

The Following 3 Users Say Thank You to outback For This Useful Post:

ppetresen (02-16-2020), ScoutHikerDad (02-16-2020), sharptonn (02-17-2020)

-

02-16-2020, 02:06 PM #17844Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

Those abrasive puffs are great. Seems like they wear pretty quickly though. Mine may have worn faster since they were a generic brand from eBay.

- Joshua

-

02-16-2020, 03:51 PM #17845

I asked Charlie Lewis about them and he said he uses them under other belts to impart a 'cushion' at times for different effects/uses.

-

02-17-2020, 04:36 AM #17846Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

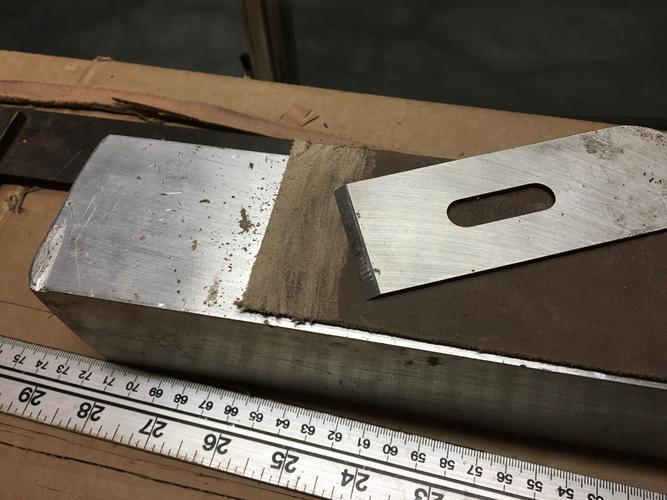

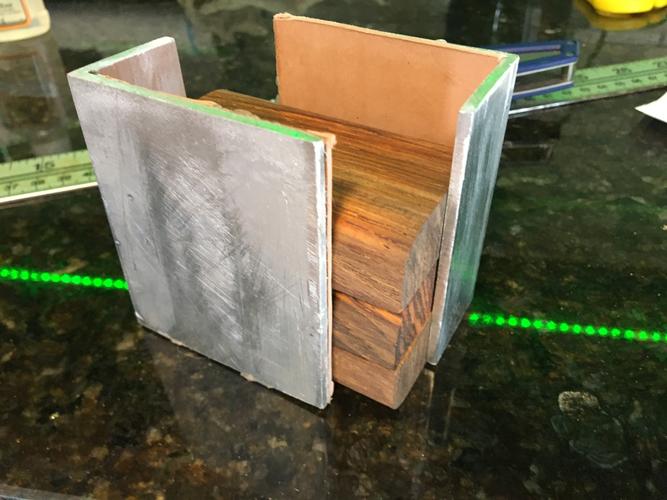

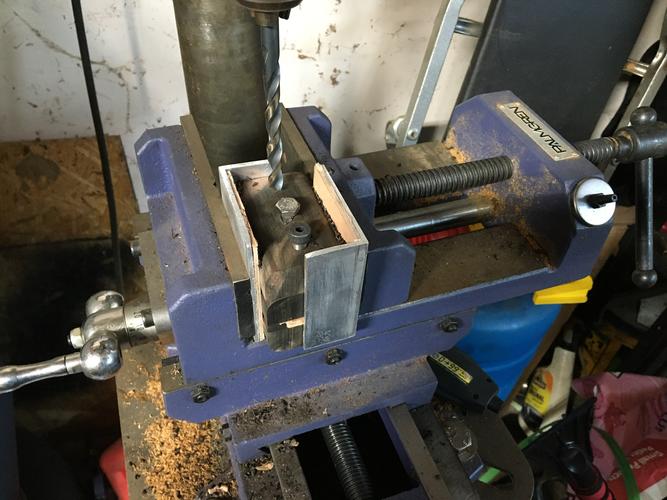

Little leather shaving and bonding.

As well as jigging up the shaft bores,

Used some square tube 2 1/2” aluminum for my leather cut guide as well as a piece ripped and modded to hold the stacks in the vice through the various hole sizes.

Trying to keep everything true and parallel throughout.

Cheers gents.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

02-17-2020, 05:08 AM #17847

-

02-18-2020, 12:59 AM #17848Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Starting to take shape.

Couldn’t come up with a better way to align things at this step,

But it worked, pretty or not.

Then mill down some mammoth ivory for bling.

Now to work on the handle(s).

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

sharptonn (02-18-2020)

-

02-18-2020, 08:23 PM #17849Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19 First attempt at old razor - 1860?

First attempt at old razor - 1860?

Thought I'd share the latest work and ask for feedback. This is a WS Turner & Co 'Heart & Mind' razor, belonging to my cousin, who bought it for £4 at a boot sale.

Here it is as I got it:

And here are the issues:

First, damage to the horn scales, cracks and some missing from pivot end of one scale.

Next, big heel hook.

Finally, blade not centering and edge catching on the scales.

Observations at this stage were that firstly the damage to the scale seemed to be far enough from the pivot to mean that the void could be filled without strengthening, and secondly that the blade has seen some sort of re-grind, and over the years has acquired a hard dark grey patina.

So, the plan was, dismantle, restore and straighten the scales, re-shape the blade, re-assemble and hone. Because of the re-grind, because the blade has seen wear, and because the patina is actually pretty cool, I decided not to re-finish the blade in any way, I could imagine spending a long time and it just looking a mess. I think this approach is in keeping with it being a humble old razor.

Here are the results:

Scales responded well to ironing, gluing, sanding, polishing and soaking in oil. The blade was originally pinned with double collars, and I managed to salvage all eight, so it was re-pinned with the original collars.

I filled the missing section in the scale with filled epoxy, and then coated with CA so it would take a nice finish. Unfortunately, I wiped the epoxy with alcohol before coating with CA, which left a white bloom. I thought it would disappear with the CA on it, but it didn't. I could have pulled it all off and started again, but I think that I could have ended up over-working it, lesson learned, and in a way it is nice that you can see the restoration.

Centering the blade in the scales was tricky. The face side of the razor is very straight, so it was tricky to avoid the face scale binding on the tang. After trying all sorts of things, including offsetting the pin holes at the pivot to put a set in the scales, and trying different thickness of wear washer on each side, I decided to try a thicker wedge to put a touch more curve in the scales. The new wedge is bone, replacing the original pewter wedge, and the new one is about 1.5 the thickness of the original at the thick end, and slightly thinner at the thin end. On top of this, I put an extra 0.2mm wear washer on one side. I know this is controversial, and for a more delicate razor I might not have done this, but it works, and without it the tang was binding on the face scale.

Last thing was removing the heel hook, something which I'm not very confident with, I always feel I'm feeling around in the dark. But I'm happy this time, the blade honed fine with nothing getting in the way, and I think the profile is ok. Luckily, the blade took a nice even bevel, and I honed it untaped after setting the bevel. Bevel angle is around 17.5º.

So, many thanks to the board, just about every technique was learned here, I am happy with this as a first attempt on a razor of this age. Horn is a really nice material to work with. I'm happy with the way it looks, and it also feels really good in the hand, so hopefully my cousin will enjoy shaving with it.

Finally a question, looking at the tail, the marks in the steel look like casting marks, is this a cast blade?

-

The Following User Says Thank You to Montgomery For This Useful Post:

ScoutHikerDad (02-19-2020)

-

02-18-2020, 08:26 PM #17850Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Looks waaaaaay better. That heel hook was crazy stuff. I’m betting your cousin won’t recognize it. Good work.

It's not what you know, it's who you take fishing!

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote