Results 7,661 to 7,670 of 20573

Thread: What are you working on?

-

02-18-2017, 01:14 AM #7661

From the Data Safety Sheet:

Trade name:

UnipolŪ Dialux green

General chemical description

mixture of fatty acids, paraffines, abrasive polishing minerals, chromoxide

After thinking about it I decided to have the writing on the box translated/it's pretty much you will find online:

The Dialux Vert is especially recommended for fine brightening with polishing, special steels, very hard alloys, chromium, cobalt chromium, platinum etc.

To be used on circular brush, felt or cotton disc.Last edited by cudarunner; 02-18-2017 at 02:28 AM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

-

02-18-2017, 01:39 AM #7662

-

02-18-2017, 01:52 AM #7663

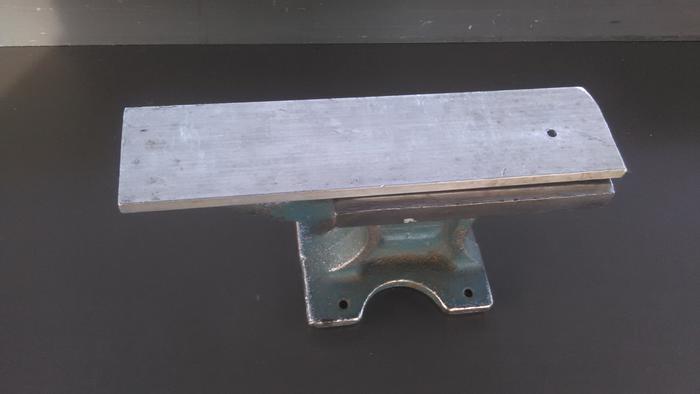

Well I been busy lately and havent had tiem to do anything but decided to try and learn how to remoce scales without breakign them. All my early attempts were failures. So I just hacked away at it on some that already had broken scales. I used a small anvil with a hole in it but seems the hole was too big and I continued to break scales. Then decided to use a piece of aluminum with a hole just big enough for the pin to go through and I started to have some succes.

These were all broken to some degree before I did anything

Then moved on to better ones. The last is a nice Dubl Duck Satin Edge set of scales that had that had an IROS KEEN blade in them. Managed to remove the blade without damaging the scales!

Now I just have to find a dubl duck to go inside them. Either that or trade them to someone for a different set of scales.

-

02-18-2017, 02:00 AM #7664

I learned early on that using a punch and hammer will result in busted scales most of the time.

JMHO

-

02-18-2017, 02:06 AM #7665

-

02-18-2017, 02:11 AM #7666

The Busch cleaned up pretty well. The perfectionist in me wants to go back and do some sanding but it really is pretty nice as is.

The wedge is a little piece of tubing. I've seen this on other razors and always assumed the it was added by someone that didn't have a spacer handy. These are obviously the original scale though and the factory style pins all match. Either way, it's serving its purpose and will stay in there.

B.J.

B.J.

-

The Following User Says Thank You to BeJay For This Useful Post:

xiaotuzi (02-19-2017)

-

02-18-2017, 02:12 AM #7667

Best explained here beginning with post #27; http://straightrazorpalace.com/works...le-halves.html

-

-

02-18-2017, 03:31 AM #7668

-

02-18-2017, 03:35 AM #7669Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

I find if my approach is to flatten the pin, start a hole with a split point bit in a pin vise and then use a drill press with a split point bit, all goes fairly well, most of the time.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

sharptonn (02-18-2017)

-

02-18-2017, 03:48 AM #7670

I use a small file to flatten and remove as much of the pin as possible and I do that on both sides as sometimes you need to 'Gently' work back and forth. I also have a pinning block that I drilled a hole completely through and then made a slight depression and that really helped!

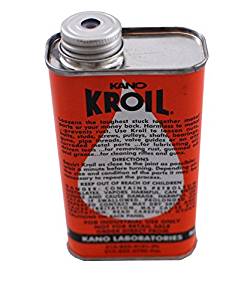

However I now use a product that I was turned onto by a friend who lives in the boonies of Idaho. I find it of great use. However it can stain bone, Ivory and certain light colored horn.

While marketed as a 'penetrating oil' my friend referrers to it as a 'creeping oil' that is widely used in gunsmithing. It's great stuff!

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

Hirlau (02-20-2017)

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote