Results 9,661 to 9,670 of 20573

Thread: What are you working on?

-

06-08-2017, 08:17 PM #9661

That's a nice one.!

I've used one for butchering deer, but I like a stone better.

Thanks for the pic Roy.Mike

-

06-08-2017, 08:28 PM #9662

That's one that I did for Gasman. I'm sure that it was NOS and that the original protecting coating was what made it look like it did. Here's a sellers pic.

Anyway it cleaned up really nice!

I've restored an F. Dick for all three of my kids, and my buddy Ski--plus I have and use my uncles who passed away in '75.

The ones that I like to use are a fairly fine one, however if you look at FleaBay you'll find some coarse ones. The man who taught me meat cutting started with Safeway in 1934 as an apprentice meat cutter, he went on to become a Store Manager for Safeway and then in 1949 he opened his own store.

Anyway he said that the coarse ones were used in the meat processing plants so that when a guy would hit a bone and ding the edge a bit the damage could be quickly fixed with the rougher steel but for a meat cutter the finer ones were best.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following 4 Users Say Thank You to cudarunner For This Useful Post:

Dieseld (06-09-2017), dinnermint (06-09-2017), outback (06-08-2017), xiaotuzi (06-12-2017)

-

06-08-2017, 08:36 PM #9663

I'm posting at work, so it's not on hand

Thanks for the removing ring ideer, I shoulda thought of that. I did oil it some, but nothing specific for penetration. Heh, astro glide might work! Lol, we should have some penetrating agent at work I can nab a bit of.

I won't actually torch it, just being melodramatic

-

The Following User Says Thank You to dinnermint For This Useful Post:

outback (06-08-2017)

-

06-08-2017, 08:50 PM #9664

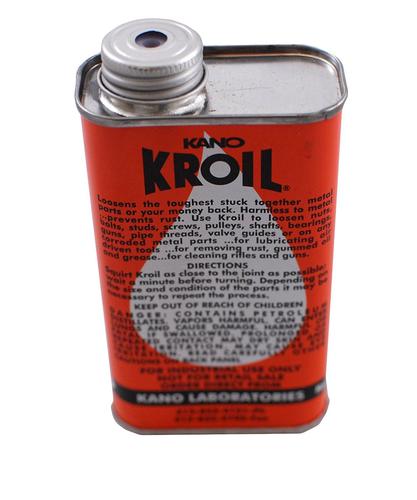

Be careful removing that ring, only bend it enough to get it out as it's a Beech to get it looking round again/I'm sure that at the factory a machine was used. Also Glen turned me onto the Absolute Best 'Creeping Oil' and it's called Kroil Oil. I highly recommend it! I also bought some 'needle tipped' dispenser for it. You can find it at Amazon:

And the small dispensers:

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

And if you only used a little bit of heat, it wouldn't hurt things but only enough to get the cap to expand away from the shaft a bit.

Let me know how things work out. Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

dinnermint (06-08-2017)

-

06-08-2017, 11:56 PM #9665

Got a little time for razors today. Made some scales (Quilted Maple I got from Cudarunner) for a Wade & Butcher. The blade is rough but I tried to help it out some.

Also got out the buffer and cleaned up a few more blades. They will need some more work and a couple of them are pitted badly but I think they will be just fine when dressed.

It's just Sharpening, right?

It's just Sharpening, right?

Jerry...

-

06-09-2017, 12:05 AM #9666

Looking good, you'll be pleased once you get that Tru-Oil on that Maple as it really looks nice.

One thing to keep in mind about using your buffer is that not every razor needs nor should have a near mirror finish. Especially the older ones as they never came from the original grinder with such a finish. The satin look is very attractive. Also if you have blades that all of the imperfections can't be removed the satin doesn't make those imperfections 'Stand Out'.

Keep us posted with the progress/especially that scale blade pair Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

dinnermint (06-09-2017)

-

06-09-2017, 03:56 AM #9667

Here's a wacky idea -- put it in a bed of dry ice long enough to reach uniform temperature (probably half an hour). Get some water to boiling. Wearing gloves, grab the steel end, and immerse the stuck cap in the boiling water. If it doesn't crack from the thermal stress, it'll probably expand enough around the frozen inner core to break the threads loose... and you won't burn the wood.

-

06-09-2017, 08:10 AM #9668

Thanks Roy. I had thought of the matte finish for the worst ones. Was figureing id clean them up best i could on the buffer, then ask the fine folks here on how to acheve the matt finish. Guessing some 400 grit paper in lots of directions would get it. And thanks for fixing up my F. Dick, Roy. The wife loves it. Although she just loves that its pretty. Im the one who uses it on her knifes.

So how do i get the matte finish folks?It's just Sharpening, right?

Jerry...

-

06-09-2017, 10:38 AM #9669

I like using a wore, scotchbrite wheel in the dremmel, after 1000 grt, wet/dry paper.

Mike

Mike

-

The Following 4 Users Say Thank You to outback For This Useful Post:

Dieseld (06-09-2017), dinnermint (06-09-2017), Gasman (06-09-2017), Mrchick (06-09-2017)

-

06-09-2017, 12:15 PM #9670

Dont have any scotchbrite for my drimmel. Guess i can see about finding some. Anyone else? BTW, thanks Mike.

It's just Sharpening, right?

Jerry...

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote