Results 3,311 to 3,320 of 4688

Thread: The Butchered Blade

-

12-28-2015, 02:52 AM #3311

Mike B52, awesome pic sequence and explanation of the electroplating process.

If they would have had cool stuff like that back in science class in school I probably would have hung around longer than I did!!

-

12-28-2015, 10:19 AM #3312

Started on my 1st restoration, a Joseph Rodgers.

Managed to find some brass 1/16" rod at a local hobby shop and also save the washes after unpinning.

The wedge has been glued onto the one scale.

Looks like the toe has been slightly over-honed in the past but the blade should clean up nicely as there is no pitting.

Last edited by Thug; 12-28-2015 at 04:36 PM. Reason: language

Tony

-

12-28-2015, 02:30 PM #3313Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Nice goin Tony!

That's a good looking Rodgers. Some hi grit wet sanding, and or polishing. Beauty reborn!"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

Thug (12-28-2015)

-

12-28-2015, 02:54 PM #3314

-

The Following User Says Thank You to WW243 For This Useful Post:

MikeB52 (12-28-2015)

-

12-28-2015, 03:04 PM #3315

-

12-28-2015, 04:30 PM #3316Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207 "Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

12-28-2015, 06:06 PM #3317

Tony, that will be a great piece once finished. The K&S brass is probably the best to use as a hobbyist. I like it all & the brass tubing fits inside the larger pieces when you have to use some of it.

Right on Bill. A new made up word is always unique in its own way plus the meaning.

Good job B52!

I finally got my cocobolo pieces flat on the inner side. Now to start on my design & cut it out & this time to carefully take a little bit off at a time when putting my contour in them. I will also mark where they are joined together.

-

The Following User Says Thank You to engine46 For This Useful Post:

Thug (12-28-2015)

-

12-28-2015, 06:30 PM #3318

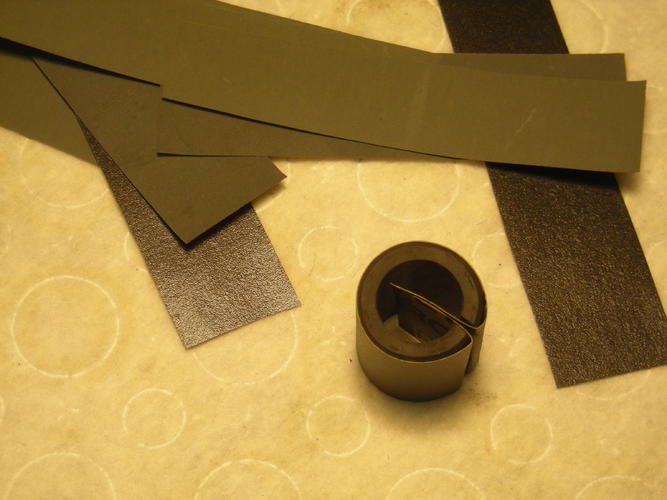

Sanding on the Quackers a bit with wet/dry and WD. I use a piece of automotive heater hose, split. Cut some strips of 600, 1000, 1500, and crocus to fit it. Cannot bring myself to begin rougher than 600 as the scratches never seem to come out otherwise.

Some rough pitting at the end and some spider veins to attempt sanding out.

I can already see loading up the crocus with CroOx and attempting a more satin finish in the end.

It IS a Satinedge!

I can go 15-20 mins at a time and have to quit for a while. Going to take a long time.

On razors double-ground like this one, I do the top grind a while and then across the bottom one.

I like to attempt to preserve the top of the bottom grind as much as possible by trying not to sand over it as much.

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

-

12-28-2015, 06:41 PM #3319Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

That's a clever made sanding block Tom.

I use some rubber shapes purchased from Lee Valley, in different profiles, but that hose idea is simple and captures the paper in the split.

Idea borrowed, and patented,, hehe"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

12-28-2015, 07:05 PM #3320

Also, there are unlimited diameters of hose, fuel hose, vacuum hose diameters to use for different things.

As I get weary of sanding, I go out to the bench with the razor/magnetic jig and use a tad of Dremel using 600 greaseless and some worn scotchbrite buffs, bring it back in for the next sanding session. I cheat as much as I can!

I hate sanding on blades more than I do honing.

With that being said, if it does not look good with 600, it ain't gonna fly. Just like moving past the 1k stone!"Don't be stubborn. You are missing out."

I rest my case.

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote