Results 3,281 to 3,290 of 4688

Thread: The Butchered Blade

-

12-26-2015, 10:24 PM #3281Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yea, when I dome washers the center stick out the bottom a bit and can bite into the scale so I sand them on some 1k wet & dry to even and smooth them out, I sand on the tip of my finger with the paper on the counter. They still bite in a bit, so I place the collar on the scale and put in a piece of rod to center the collar on the scale. Then I mark it with a dot of sharpie in 4 places for final placement when pinning. WD40 removes the sharpie ink when finished.

I do believe the center of the scale would be better if it did not touch, than touching as the pressure would pull the collar down tight and be under tension in compressive stress, the old architectural arch theory. I suspect that may have been the original purpose of doming collars rather than using flat a washers.

I too have some of those also and looking forward to see them pinned.

-

12-26-2015, 10:49 PM #3282

Well everyone is working on something!!! Guess I'll see what I can do with the Joseph Allen NON-XL MikeB sent me.

Should be a good challenge for me, for the tang is bent and the blade has a twist in it. Kinda typical I hear though. Also has chips from heel to toe. Picked up some black n white ebony today for the scales

So it looks like Tom and I are on the same wavelength [emoji1]

Mike

Mike

-

12-26-2015, 10:55 PM #3283Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,398

- Blog Entries

- 1

Thanked: 4202

I agree, that duck's going to be a beetlejuice clad beauty when you are done Tom.

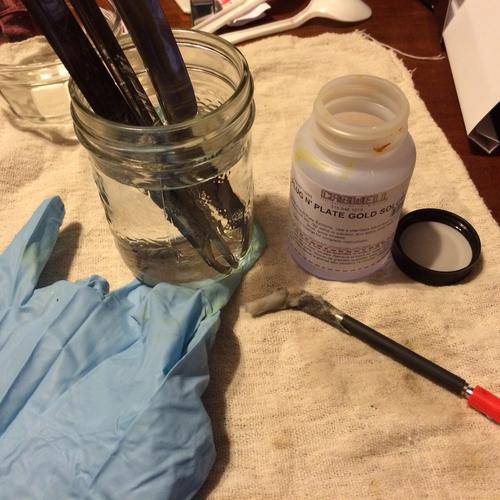

Following up on my cladding trials I got them done.

For prep I washed the blades, then soaked em in white vinegar for a few minutes. Note the used 'wand' applicator still plugged in. See how the oxidation accumulates on the anode wrap. Wash that well between uses and it last a while.

Then rinsed them and let them soak in hot water while I made up the bath deciding I will dip them up to the tangs and then coat the spines via the brush. I tried to just brush the entire tang and did not like the results for even coating so came up with a new plan.

Finally ready, I poured a shooter glass full whiskey, and another full of gold solution. Drank the whiskey while heating the solution in the microwave for 30 seconds.

Cladding goes much more quickly and uniformly when everything is hot. Needs less current too.

The actual application I couldn't film as I needed both hands to hold the blade, and the wand in the shooter glass without touching each other. Opted for that particular glass to use the least amount of solution to get to the exact height I wanted with the blade in the glass, tang first.

The actual application involved attaching the return electrical gator clip to the blade above the glass height and immersing it in the glass with the wand. You want the same amount of wand and metal in the bath so they go in and out together. Once in, there is electrical bubbling and fizzing going on as the gold bonds to the blade. Swirl the blade slowly and keep it in there till the application is to your liking. Pull um out, wipe down gently and dry. All told, repeated the dip process 4 times for each blade, then I redid the DE handle till there was no more bubbling in the glass. That way I used up all the solution and dumped the liquid that remained in the glass as opposed to pouring it back into the original bottle and risking contamination of the remaining gold ..

Hard to get the spine shot but they turned out pretty well. Going to try a gentle polish on them and see if they stand up. May need a few more dunks. Not sure how many is normal in the original process.

Cheers."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

12-26-2015, 11:20 PM #3284

Mike, is that gold as in gold?

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

12-27-2015, 12:00 AM #3285Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,398

- Blog Entries

- 1

Thanked: 4202

Yup, 24 k in suspension in some kind of fluid. The dc electrical current between the blade and wand cause the gold to plate onto the blade. Almost like it was done originally.

Plating kits are available at Caswell."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

WW243 (12-27-2015)

-

12-27-2015, 01:13 AM #3286

-

The Following User Says Thank You to engine46 For This Useful Post:

MikeB52 (12-27-2015)

-

12-27-2015, 01:38 AM #3287Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,398

- Blog Entries

- 1

Thanked: 4202

I find a shot of whiskey never hurts a project Steve. More than one might be detrimental, but one is just nice. Andsince I was getting one glass out, why not two, hehe.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

12-27-2015, 02:01 AM #3288

-

12-27-2015, 02:20 AM #3289Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,409

Thanked: 4824

MikeB

I am intrigued to say the least. You did the tangs and the spines but not the blade. What keeps the gold from getting on the blade?It's not what you know, it's who you take fishing!

-

12-27-2015, 03:54 PM #3290Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,398

- Blog Entries

- 1

Thanked: 4202

Morning gents, back at it today.

To your question Shaun, and since I had good wifi this am before my kids woke up I added some more pics.

For the immersion step, everything is coated that is in the solution, as from an electrical perspective the positive is the wand and the negative is the blade. So (theory part) electron flow and gold particle flow is to the blade as voltage flows to the wand, or something like that. Basically for the dip, the 'water' line is key as that's the highest point the gold will be applied.

For the brush on step, same electrical process applies wherein the s.s. wand and blade are at different electrical potentials. Wand positive, and blade, once connected, is negative.

The gauze type wrap is soaked in the liquid gold and wrapped around the wand tip, which is flat profiled.

When brushed against the blade, the circuit conducts through the point the wand and blade meet. The gauze must be completely around the s.s. wand. Any exposed metal causes arcing and burning of the steel.

Had very good control by basically keeping the flat of the wand aligned with the area of the blade I wanted cladded. While the liquid would run down the blade and drip some off the gauze, there was no electricity driving the dripping gold so no cladding occurred except where I wanted.

So, soak tip, apply to a small 1" area for about 30 seconds constantly moving the wand. Reload the wand tip in solution from a smaller container of solution, not the main jar to avoid contamination. Continue down the blade until the depth of gold is achieved.

I've moved on to trying to reblue the tang marks today while my hands are still relatively steady, hehe. Using Testor Medium Blue enamel and then scrapping off the excess with a toothpick under high magnification.

Hope to have these back in their scales today.

Thanks for asking about the process. I think it's got some pretty cool potential between the gold I am using on this one, black chrome in lie of bluing maybe on a few others, maybe brass or copper cladding on a few scales as well. Lots of ideas.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following 11 Users Say Thank You to MikeB52 For This Useful Post:

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote