Results 1,661 to 1,670 of 2526

Thread: 51 MG restoration.

-

05-05-2022, 02:51 AM #1661

Boy, sure looks to me like extending those rods would be the cleanest looking end product but dropping the tranny back out is a big pain in the @$$. I know it wouldn't look original but I always liked the shifter on my '69 Mustang.

Of course that exact thing wouldn't fit but maybe changing the angle to a 60°-80° curve (or would that be 100°-110°? Anyway, closer to 90°)with a short vertical portion might make it...if you can live with the look of it.Last edited by PaulFLUS; 05-05-2022 at 03:02 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

05-05-2022, 03:14 AM #1662Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Yeah the gooseneck won’t work as the throw would get really exaggerated and still be on an angled plane.

Best bet would have been pull the engine and tranny and do the bench work but f—k that.

What buddy did with his linkage in that vid Tom shared will totally fill the bill, and allow me to have a proper looking vertical shift still, and a relatively tight throw still.

I knew the relocation of the engine would or could still be an obstacle when I got to this point, just need to work the problem to an acceptable outcome inline with the investment."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

05-05-2022, 01:16 PM #1663

You can do it, Mike. The Tie-rod looked like a good idea as long as you can find enough support for the mounting plate. It will work!

It's just Sharpening, right?

Jerry...

-

-

05-06-2022, 02:05 AM #1664

..................

-

05-06-2022, 10:05 PM #1665Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

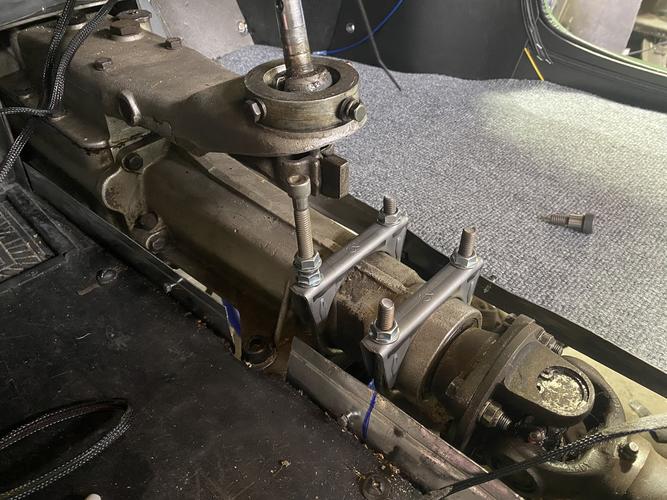

Think a plan is made, thanks to suggestions and that video.

Couple 3” clamps, not too tight to hurt the casting as my base, spanned by a series of aluminum plates @1” thickness.

Should give me the landing for the tie rod shifter.

Will be a stack up like this, final height still to be determined as I want the new shifter lower, with a tight throw still.needs to step back in stages as I need to have it start hanging over those socket head bolts so I can run two 1/4-20 leveling feet down to assist in the lateral stability. They will engage the socket heads but not be drilled into the mounts, the 2 clamps will provide the real clamping force.

Then it needs to step back so the third gear shift position doesn’t hit the plates themselves, then it needs to step up a bit more to ensure the forward u joint has clearance.

But all of it will fit under the tunnel with a new mid piece and will be very solid and all bolted together.

Will do the bulk of the retooling on the weekend and cut the tie rod down and thread it to 7/16 fine pitch for the shift knob next week at work.

Finished the boot and installed the carpets and door trim as well.

And I’m please with the new lower hatch, just as unobtrusive as I hoped.

Went with a flush mount marine hatch latch as it sort of had the look I wanted and is waterproof.

All in all happy with the progress, and the plan.

This car now has 2 AC Delco parts on her. "Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

05-06-2022, 11:07 PM #1666

Looks good! Think about some steel square or rectangular tube instead of the aluminum blocks?

You could weld to the muffler clamps and have a piece across the 2. Drill a hole and have a nut tacked-up inside to screw your tie-rod into.

-

05-06-2022, 11:10 PM #1667

The worst that will happen is that you will have to hit the clutch and the brakes then the off switch.

-

05-07-2022, 12:01 AM #1668Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

I may indeed end up going steel welded plates, need to work out the fine details tonight and poke through the scrap bin at work tomorrow for stock.

And I’ll be threading the mount to m22 and screwing the rod into that, no lock nuts needed.

Might need to build an offset into my connector arms to account for the difference in height, but hell, I’m only doing this once so put it in my perfect shift spot right?"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

05-07-2022, 01:44 AM #1669

Yes, I was thinking you might do a bend or two in your shaft and get the shifter down some.

-

05-07-2022, 02:57 AM #1670Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Because of the additional accessory panel I will benefit from dropping it down, make sure I have good knuckle clearance. Figure if I add a drop in the connecting linkage equal to the offset of the two pivot points it should still work balls on. Figure I should be good at 1/4” shoulder bolts as my pivots. Don’t have a lot of meat on that original shifter to go up a size or consider bronze sleeves or anything fancy.

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

8897Likes

8897Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote