Results 13,871 to 13,880 of 20573

Thread: What are you working on?

-

08-24-2018, 08:57 PM #13871

Looking good there!

Not making any scales, but restoring some!

Steve's hot-iron trick and some epoxy/bog oak dust repairs.......

-

08-25-2018, 12:28 AM #13872

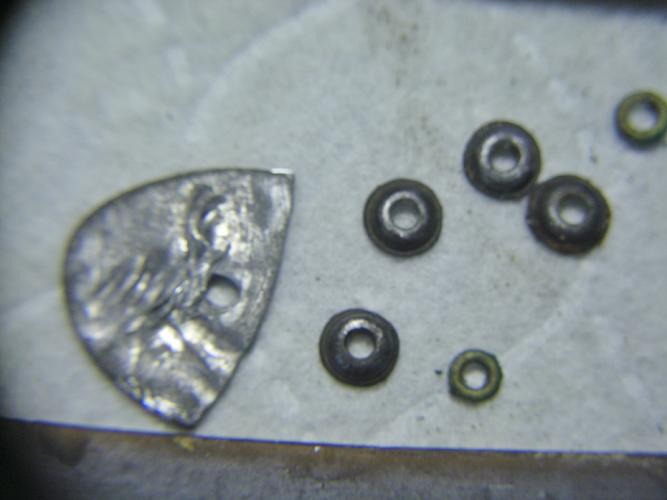

The bottom on the top pictured scale was broken in-half.

THAT is how you drill through the middle......

Been working on them for a few days.

No oil til I am done. Amazing how easy it is to work with this stuff when dry.

CA stuck that end back on like a rock. Some wire-bush toothbrush and blowing out the dust makes for great adhesion.

I WILL likely CA the wedge to that side!

Salvaged some perfect steel collars/undercollars. Look at the wedge!

Put in hot?

Old thing had never been apart!

Last edited by sharptonn; 08-25-2018 at 01:09 AM.

-

08-25-2018, 03:34 AM #13873

After a trip to the grocery store with the wife, I got these drilled, mocked up and bone wedges made. My fingertips hurt!

And yes, the wedges have the same angle as the tang. All the blades center nicely.It's just Sharpening, right?

Jerry...

-

-

08-25-2018, 11:04 AM #13874

No pics as of yet, but I've been working on a Frederick Reynolds.

Its been unpinned, the scales sanded with 220,400,600,and steel wooled, polished, and reside in a coat of Neats foot oil. The blade sits in the magnetic jig, partially sanded.

Hopefully it comes out as nice as my other.

Mike

Mike

-

08-25-2018, 11:20 AM #13875

I really need to make a blade jig!

That blade is very well done.

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

outback (08-25-2018)

-

08-25-2018, 11:25 AM #13876

Their nice to have, Mike. Makes sanding n such so much easier on the hand's.

Mike

-

08-25-2018, 12:09 PM #13877

Hah! I'm feeling it now!

Been working on a double concave lately (will get pictures later), PITA. My hands are a bit sore. Saw that jig and smacked myself in the forehead.

I remember my grandpops, he used to say something along the lines of prepare your work space and tools so that the execution of the job is pure and not hindered by actions from what should always be "prep-work".

The jig is a beautiful example of prep now, enjoy later!

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

08-25-2018, 12:27 PM #13878

A few past threads on them, you can do a search as there were many in the what are you working on forum. There ae no hard and fast rules as to how to make them

magnetic-razor-jig

Razor jig post#7592

Have fun!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

-

08-25-2018, 12:38 PM #13879

-

08-25-2018, 01:09 PM #13880

I forgot to add that the slots on the jig in post #7592 look like a must have to work on the spine. Perhaps a second jig for those..?

Work smart is the concept I'm sticking with.

Also I want to add that seeing all of the threads and posts on the forum lately has been a humbling experience for me. My friends would laugh!

I need to unlearn some things, and take some lessons. Thanks for the constant flow of info!“You must unlearn what you have learned.”

– Yoda

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote