Results 18,871 to 18,880 of 20574

Thread: What are you working on?

-

09-05-2020, 03:37 AM #18871

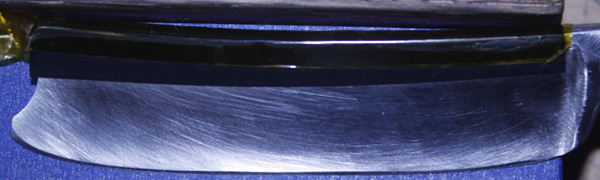

I decided to try one of gssixgun's tricks and ground a layer of tape down to fill in low spots on the spine. Then I added a layer of kapton tape and started on checking the bevel. It's not fully set yet but looks pretty even to me. The tip has started getting a bit chippy again, so I'll keep at it a little longer.

Oh, and honing without scales is still weird. I know, I could do the Popsicle stick/tongue depressor scales, but I'm being lazy and I don't like dealing with the bolt sticking out. I'll probably finish the bevel tomorrow, kind of had my fill for tonight.O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

09-05-2020, 04:12 AM #18872Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

If you look straight down on the edge an the flat ares is upper even then it’s likely ok. I might call it good there and start progressing though the grits, as long as there were no fat or thins spots on the point of the bevel. If you go all the way you should dull I it before sanding.

It's not what you know, it's who you take fishing!

-

09-05-2020, 04:55 AM #18873Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

Just playing with a leftover piece of zebrawood from a previous project

It's drilled with a 1" hole, 16mm deep, to leave a 49mm loft on a knot I've got here. Handle is 2" tall, 1 3/8" at the widest point

Didn't quite turn out the shape I intended, but it's not a bad shape I guess.

Not sure it's going to work out though, this stuff has crazy big pores, and some voids I wasn't expecting. Will have to look at it again over the weekend to decide what to do

-

09-05-2020, 12:58 PM #18874Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

I’m curious if you could fill the voids in a vacuum chamber with stabilizer and Make it more serviceable. It looks very nice.

It's not what you know, it's who you take fishing!

-

09-05-2020, 01:19 PM #18875Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

Thanks Rez

The wood is pretty oily, I'm not sure that it would play too well with the stabilizer I have (cactus juice). And that stuff also requires baking to harden...i probably could've tried that on the blank, but i think the heat would just split the thing in its current shape.

If anything, i was thinking wipe it down with a bunch of DNA to strip the oils from the surface, then try to get some type of hardening, penetrating finish to soak into the wood a bit, before sealing with a thicker finish to fill the gaps...layer that up thick, then sand/polish smooth.

Happy to say I made some major improvements with the time spent on the grinders the last couple days though. Adjusted some bevel angles, tweaked some grinds....the cutting went WAY better on this than on that chisel handle I posted! I actually degraded the surface when I decided to sand it with 500 grit lol

-

09-06-2020, 12:06 AM #18876Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

-

09-06-2020, 12:39 AM #18877Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Believe Rez is referring to the irregular thickness aggressive hand sanding can cause along the blade faces if you arenít careful. They will show up as thicker or thinner width of bevel as you redefine it. The apex will still be straight, but the back of the bevel will wander as the blade thickness changes..

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

RezDog (09-07-2020)

-

09-06-2020, 01:00 AM #18878Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Awesome, thanks MikeB52 (pilot?). This is good to know.

-

09-06-2020, 02:52 AM #18879Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

Yup mike is correct. That’s is what I was talking about.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

planeden (09-06-2020)

-

09-07-2020, 09:41 AM #18880

That is why I use a round sanding jig to wrap paper around. Lots of post earlier about that. A wood dowel works or a wine cork. I have one specifically made for sanding I like because it is longer than a cork but sometimes the shorter one is good for sanding stabilizer to tang and grind to stabilizer transition cracks where lots of gunk can hide. If I'm going to do very much sanding I try to even out the number of strokes heel to toe and side for side to keep the geometry even, unless of course I am trying to correct the geometry because of an uneven grind.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

91475Likes

91475Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote