Results 8,871 to 8,880 of 20602

Thread: What are you working on?

-

04-12-2017, 01:55 AM #8871Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I'm with Roy on this one. I quite often start with three and drop to two. There are very few near wedges that I can hone with a single layer and have a sensible bevel. Too much tape effects the shave too. You need to be in the happy zone. It can take many sessions to get a properly set bevel on a near wedge. I try to limit how much time in one session I spend on bevel setting on restoration honing. I think if I spend too much time in one sitting working on one razor it is al,out counter productive. Like I get bored and stop paying enough attention and then I'm not honing anymore I'm just grinding away.

Relax and enjoy, when that stops you should too!It's not what you know, it's who you take fishing!

-

The Following 6 Users Say Thank You to RezDog For This Useful Post:

cudarunner (04-12-2017), Dieseld (04-12-2017), dinnermint (04-12-2017), Gasman (04-12-2017), sharptonn (04-12-2017), xiaotuzi (04-12-2017)

-

04-12-2017, 02:04 AM #8872

-

The Following User Says Thank You to cudarunner For This Useful Post:

Gasman (04-12-2017)

-

04-12-2017, 02:41 AM #8873

Problem with these old-school edges is they need to be developed by the strop.

The impatient ones will give-up a few shaves away from perfection as they are...Impatient!

-

The Following User Says Thank You to sharptonn For This Useful Post:

Gasman (04-12-2017)

-

04-12-2017, 02:57 AM #8874

I know there are far more experienced people on this forum than I when it comes to honing razors (although I do have several decades' experience of honing knives and woodworking tools). But in case it's helpful to others, I wanted to share what worked for me when I was trying to understand how to hone a smiling razor.

I've been able to do this successfully a few times now, and here is what made it click for me -- maybe it'll be useful for someone else too.

I watched videos and listened to experienced people talk about rolling strokes, but I had to get to a point where I could envision what I was doing.

So I thought of an exaggerated version -- a bicycle wheel with a hub that sticks out. When I think of the razor as a section of that bicycle wheel, with the hub of the wheel as the spine and the tire as the edge of the blade, then I can clearly see that plowing straight ahead isn't going to touch the edge all around on that blade. You can see what I mean in a picture like this one.

If you wanted to push that wheel around on the floor in such a way that the tire is getting evenly scraped all around, you'd have to rotate it as you go. And that's what the rolling stroke does.

Rolling strokes got a lot easier for me after I started thinking of them that way.

Just thought I'd share in case it's helpful for other inexperienced people like me.

-

The Following 10 Users Say Thank You to jmabuse For This Useful Post:

AlanQ (04-12-2017), Dieseld (04-12-2017), dinnermint (04-12-2017), ejmolitor37 (04-12-2017), Gasman (04-12-2017), Geezer (04-12-2017), outback (04-12-2017), Phrank (04-12-2017), sharptonn (04-12-2017), xiaotuzi (04-12-2017)

-

04-12-2017, 03:13 AM #8875

-

04-12-2017, 03:38 AM #8876

OK! This isn't Razor Related but it was an Interesting, Important and Very Rewarding Project.

I've posted time and time again how my old buddy Ski has helped me with projects that involved wood as he's an excellent woodworker. See here for a couple of razor related projects:

http://straightrazorpalace.com/razor...forgotten.html

http://straightrazorpalace.com/works...ml#post1372123

http://straightrazorpalace.com/works...ml#post1721182

A little background is in order: Ski's father was a carpenter and cabinet maker.

Ski's dad passed away in 1990 and Ski inherited his dads tools including a vintage Craftsman 10" table saw that I'd call 'Semi Portable' as the motor alone has to weigh between 35-45Lbs! That was back when Sears actually sold quality tools! The saw was manufactured in the mid to late '50s.

Ski grew up in the home that his father built from the ground up including 100% of the cabinets inside that home and those cabinets were made with that old Craftsman table saw.

So Ski did some research and by God Sears still carried the cast iron extension wings for the saw and he bought them. He also had a frame built for the saw to be bolted to.

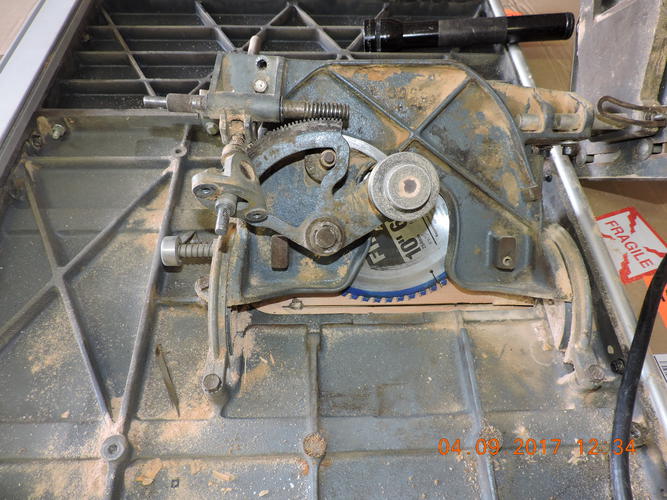

Very recently right after Ski helped me and my son build his reloading bench his saw had an Aw Crap! When he went to raise the blade it would 'skip' and not pick up the next tooth. If you relieved the tension from the weight of the motor then the blade would rise.

So after receiving a lot of friendly crap about how it was all my fault about the saw, we tore it down.

My friend Benz and fellow member here at SRP was a great help with this project and I thank him. Between him and a local machinist it was determined that while there was 'some wear' on the worm drive and the teeth however it wasn't enough to prevent the unit from operating properly. Both machinist said to clean the crap from the worm drive and the driven teeth. Also to remove the shafts from the pivot bores and clean any crap and old grease from them and then re-grease them.

I did as the experts said to and then re-lubed the gears, teeth shafts and bores.

I learned more than I can explain about how little it took to change the way the worm drive contacted and effected the driven teeth. My hat's off to who ever originally designed that system!

Anyway, Ski hasn't sent me the pics of the completed project but here's some pics of the project.

The way that the 'tension' is applied is by the weight of that old motor.

Worm gear to driven teeth prior to apply grease.

This unit only got cleaned up and had liquid graphite applied as it controls the adjustment between 90 to 45 degs.

I'll post pics of the saw on the the mobile stand once Ski gets them to me.

Thanks for looking! :

Our house is as Neil left it- an Aladdins cave of 'stuff'.

:

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

MikeB52 (04-12-2017)

-

04-12-2017, 03:43 AM #8877

Jerry I seem to have little luck honing near wedges I have one that I can not get! I go at it every now and again but I think I'm gonna send it out. But it looks great and I'm sure you'll get it.

Sent from my SM-J320R4 using TapatalkNothing is fool proof, to a sufficiently talented fool...

-

04-12-2017, 04:11 AM #8878

Thanks all for the kind words and comments. I'll take my time and go at it in a few sittings if this is what is needed. And start with 3 layers.

@jmabuse, You hit the nail on the head. I too have learned to hone with the rolling stroke from two such items put in my hand. One was a dinner plate and the one showing me explained the same thing about getting the entire edge to touch for honing. The other item was a huge, smiling razor. This thing had a smile from hell. He put it in my hands and said think about what your doing and make the edge touch the stone thru the entire stroke. At that time it just clicked. If I'm going slow I can see whats happening and it just makes sense. BTW, This gentleman that showed me this was our own @Bluesman7. Thanks Vic for making me understand!

And Roy, Thats a nice project and you did a fine job cleaning those gears up. Should work like a dream now. I'll be sharpening tomorrow! It's just Sharpening, right?

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

jmabuse (04-12-2017)

-

04-12-2017, 10:41 AM #8879

-

The Following User Says Thank You to outback For This Useful Post:

Dieseld (04-12-2017)

-

04-12-2017, 10:46 AM #8880

Yes sir, we're beef and grain here. Well not too much beef anymore. A few head to keep dad happy, we used to run over 600 head.

Worked at a dairy....nope not for me

Square bales are not my favorite either Brother, but we do a few every year. About 300 or so.Look sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote