Results 5,441 to 5,450 of 20573

Thread: What are you working on?

-

11-12-2016, 02:50 PM #5441Fizzy Laces Connoisseur

- Join Date

- Dec 2009

- Location

- Scotland

- Posts

- 1,562

Thanked: 227

-

11-12-2016, 03:32 PM #5442Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,451

Thanked: 4829

An important factor when making scales is that they are thin enough to have the flex to hold the pivot firm through the rotation of the blade, so if you are changing the materials that the scales were made out of, that also effect how thin the materials need to be. Some materials do not flex easily and need to be a little thinner than the originals. Some rimes it is a little trial and error, that is when mocking up with nuts and bolts is handy. As far as tapering them goes, I do that sometimes but mostly start with flat material and just because of shaping I may wind up with a small amount of taper but not really on purpose. To me a very small amount is a couple hundredths of an inch, nothing dramatic or noticeable. I have noticed some very slight tapers in some of the old scales.

It's not what you know, it's who you take fishing!

-

11-12-2016, 11:01 PM #5443Fizzy Laces Connoisseur

- Join Date

- Dec 2009

- Location

- Scotland

- Posts

- 1,562

Thanked: 227

Decided I had taken enough metal away and decided to leave some 'character' pitting and polish the blade up before redressing it.

This is up to 800grit.

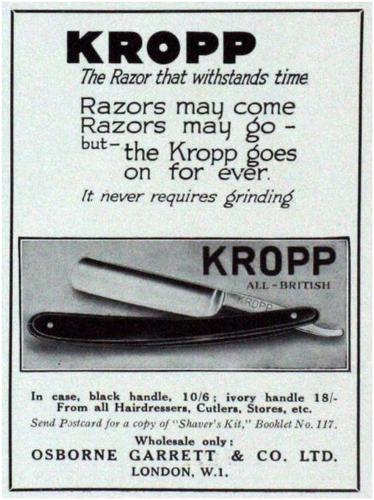

Incidentally. Does anyone know how to roughly age a KROPP? It only has the KROPP marking on it. Nothing else at all.

Geek

Sent from my LG-H850 using TapatalkLast edited by TheGeek; 11-12-2016 at 11:03 PM.

-

11-12-2016, 11:07 PM #5444

-

11-12-2016, 11:15 PM #5445Fizzy Laces Connoisseur

- Join Date

- Dec 2009

- Location

- Scotland

- Posts

- 1,562

Thanked: 227

-

11-13-2016, 12:05 AM #5446

-

11-13-2016, 12:25 AM #5447

I've got these 'Twins'

done for a friend and ready for honing.

done for a friend and ready for honing.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

ScottGoodman (11-18-2016)

-

11-13-2016, 12:34 AM #5448Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

Geek, thats an interesting Kropp, 1st there is no other markings on the razor others then Kropp, 2nd all the Kropps razor ive seen are round point. Not sure if the razor was altered with, guess its possible, looking at many advertisement for Kropp razors there is no mention of different point but different scales and sizes all with round points.

Possible that the markings were etched rather then stamped and faded away or sanded away, nevertheless because of the shape i would say that this blade is later production 1925+ seems like the earlier Kropps were more curvy on the spine and tail.

-

-

11-13-2016, 01:13 AM #5449

That is a great point thanks. The original or bake lite or black celluloid maybe I am not sure I am going to horn which was 1/4" thick or close and the original scales were .130 at the thickest point and thinned out just ever so slightly, so I was going to shoot for .130" over all and see where that gets me. I honestly never thought about the different materials flexing differently glad you mentioned that.

-

11-13-2016, 01:31 AM #5450

I scratch up the contacting sides with some 80 grit. Then i use this epoxy..

https://www.systemthree.com/products...epoxy-adhesive

I clamp the sides together with binder clips.

Most of my process follows what i learned from Bill Ellis' CD.. Just want to give credit where it's due.

-

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote