Results 7,591 to 7,600 of 20602

Thread: What are you working on?

-

02-12-2017, 04:06 PM #7591

I made mine from memory.

I had remembered reading about it, but never could find the post. But there is a pic in the library, under restoration.

Its probably not exact, but it works just fine.

I epoxied the mags, and the whole top, covered it in wax paper, and put one of my hones on top. That way once it was cured, the surface was completely flat. If I should grind a groove into the surface, I can recoat with epoxy again to make it flat.Mike

-

The Following User Says Thank You to outback For This Useful Post:

Geezer (02-12-2017)

-

02-12-2017, 04:51 PM #7592

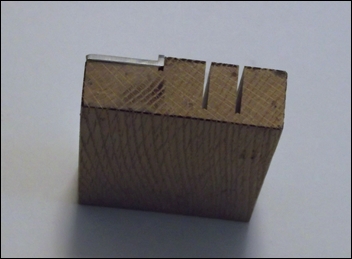

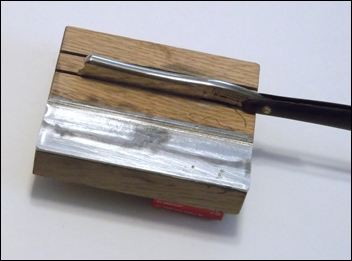

A handy addition to the basic mag holder:

Two or more slots, deep enough to allow a blade to not bottom out when working the spine and tang:

Made my life easier!

Have fun!

~Richard

-

-

02-12-2017, 05:04 PM #7593

Great idea, Geezer!

-

02-12-2017, 05:11 PM #7594

According to Randy, they only had the slots before Bill did his magic.

~Richard

-

02-12-2017, 05:15 PM #7595

Sweet, outback! A small wheel going up against the bottom of the spine will also erase most of old hone wear width using two steady hands and some practice. It is still there, yet not as prominent.

A flex-shaft is also quite nice for this endeavour.

Beauty, Tuzi!

-

-

02-12-2017, 06:56 PM #7596

Tuzi that blade looks great. Bevel really pops.

Nothing is fool proof, to a sufficiently talented fool...

-

The Following User Says Thank You to ejmolitor37 For This Useful Post:

xiaotuzi (02-12-2017)

-

02-12-2017, 06:59 PM #7597

-

02-12-2017, 07:07 PM #7598

No mags in the slots. My hand is large enough to hold the blade in place when working a tang. Otherwise friction holds well for sanding and polishing.

-

The Following 5 Users Say Thank You to Geezer For This Useful Post:

Dieseld (02-12-2017), ejmolitor37 (02-12-2017), outback (02-12-2017), sharptonn (02-13-2017), xiaotuzi (02-12-2017)

-

02-13-2017, 03:04 AM #7599

-

02-14-2017, 12:08 AM #7600Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Here is the completed P <3 Ford. I tried to keep it old looking and attempted a satin finish on the scales. I wet sanded them to 2K and then used dry 000 steel wool on them. I'm nor certain it is really the look I wanted. I struggled hard with getting the lead wedge correct. You would think by this time I would know how to do that. Three mock ups and three different wedges later I did get it. I was starting to think I needed to come and read some other people posts on how to make wedges, clearly my technique was not working. I got it together and it will go in the tombe honed box I am taking to work with me. I have some scale carvings and some honing to do while I am there so all should be good.It's not what you know, it's who you take fishing!

-

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote