Results 8,591 to 8,600 of 20573

Thread: What are you working on?

-

03-29-2017, 02:55 AM #8591Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

The bone and horn slabs are a byproduct of agriculture and are a very sustainable industry, and produces such a beautiful end product, I think they are pretty perfect for our uses. I can't imagine what I will do with the G-10 and sheets of plastic I have lying around. I think I am pretty hooked on this product line, even if it is a little more expensive.

It's not what you know, it's who you take fishing!

-

03-29-2017, 03:00 AM #8592

G10? Wot colors do you have? Green acrylic?

Faux tortoise...Faux pearl.

Like to have a bit of each!

I have trading fodder!

Last edited by sharptonn; 03-29-2017 at 03:03 AM.

-

03-29-2017, 03:01 AM #8593Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

G10 that like particle board furniture...

-

The Following User Says Thank You to Martin103 For This Useful Post:

RezDog (03-29-2017)

-

03-29-2017, 03:03 AM #8594Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

I don't know any more. I have not looked in that box for some time. I do know I bought some to make a box out of and some thinner material for scales. I don't like it. It is a pain to work with. I will email you when i get home from work.

It's not what you know, it's who you take fishing!

-

03-29-2017, 08:08 AM #8595

How about a link to those washers? They look like some fine work. And you did them justice. Thanks for explaining.

It's just Sharpening, right?

Jerry...

-

03-29-2017, 10:18 AM #8596Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

The Following 4 Users Say Thank You to Martin103 For This Useful Post:

AlanQ (03-29-2017), ejmolitor37 (03-30-2017), Gasman (03-29-2017), Hirlau (03-29-2017)

-

03-29-2017, 12:59 PM #8597

Got it. Thanks. Ordered the ni-silver and brass. Also some spacers. Now if i can hold off pinning my project razor for a month. Ha.

It's just Sharpening, right?

Jerry...

-

03-29-2017, 04:28 PM #8598

Nice job on the razor, Martin. It really came out a good one!! I'm a fan of the little bevel in washers too. A little time spent at the end with some very fine sandpaper and polish, it's all the little details that add up to the whole. Also, pins done this way feel nice in the hand, no rough edges. Great job!

"Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

Martin103 (03-29-2017)

-

03-29-2017, 05:33 PM #8599Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

+1 to all the above^^^^^^^

Fantastic peening work there Martin! And a great overall completed restore. Well done sir.

Shaun, not to pinch from Tom's box but I'd be interested in a lil swap o materialoski as well mate.

Getting some initial time in on the cnc project and learning why this is not an easy 'off the shelf' artform, or tech form or whatever you want to call it. Making lots of scrap wood out of my scrap pieces, so I have kindling covered for the next few months. But I am seeing constants emerge that I am learning from.

Almost ready to tackle some Otto font I think.

Cheers gents."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

03-29-2017, 10:17 PM #8600

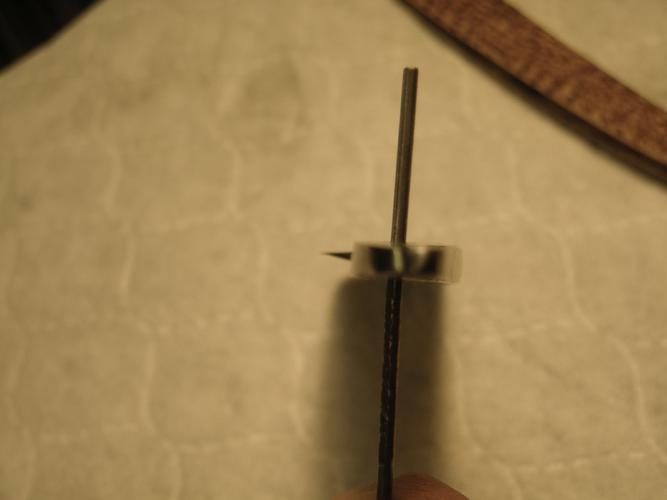

Here is a strange one...

Old Torrey. One of the early examples made by Turner, possibly piecework from Connecticut prior to his joining forces with Torrey.

Pinned it up collarless a long while back. It would close center, but as you opened it backwards and then closed again, it might hit the front scale unless you pushed the blade forward. Could not figure it out and, what with collarless peens, did not want to experiment further. It went to live with a friend for a while...

Told him to watch it as he closed it.

Fast forward a few years and some horse-trading got it back into my hands.

Yup..Same issue still there.

Drilled the top-pin out and decided to SEE what was up.

Found that I remembered that the Sheffield-trained Mr. Turner made pinholes the old way.

Punched-in and oversized.

So I popped in an aluminum pop-rivet, peened the aluminum mandrel into the middle and set-up to drill a new 5/64 pin-hole at the rear of the spectrum.

Like this.

So as turning over the razor I see THIS!

WTF? I know I had the spine level and the tail supported...Drill went straight through?

Stuck a mandrel in...Level...Level...

Oh well..Test fit had it closing perfectly no matter what!

So I have concluded the original hole was struck-in at a fairly good angle for some reason. Go figure!

I theorize that as the blade moved back on the pin during full opening and re-closing... The pin encountered a slanted surface...And it tilted the blade. That!

Got it all pinned back up. Right as rain.

Always something new to see!

Last edited by sharptonn; 03-30-2017 at 01:31 AM.

-

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote