Results 7,821 to 7,830 of 20574

Thread: What are you working on?

-

03-01-2017, 10:55 PM #7821

Typically I do my horn repairs in epoxy, then dish them out slightly, then top them off with CA. Being the epoxy usually doesn't polish up, but the CA will. Like clear coating paint.

Large amounts of CA tend to bubble from off gassing, that's another reason for the use of epoxy ( mix it with the bog oak Dave )Mike

-

-

03-02-2017, 01:45 AM #7822

Got it thanks Mike

Look sharp and smell nice for the ladies.~~~Benz

Look sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

The Following User Says Thank You to Dieseld For This Useful Post:

sharptonn (03-02-2017)

-

03-02-2017, 03:09 AM #7823

-

03-02-2017, 03:22 AM #7824

When I do the dust/epoxy repairs, I never oil them til the end . I like to blend in the epoxy repairs as best I can by following the grain of the horn with coarse sand paper down to fine steel-wool. Get em like you want em! I also like to 'Paint' them with a Sharpie Magnum, rubbing most of that off as well.

Apply Neetsfoot to the scales heavily with a q-tip all over. Flip and rub it in for several days.

Wipe and done!

I don't think attempting a 'glass' finish is prudent.

I, for one, appreciate the grain of the horn.Last edited by sharptonn; 03-02-2017 at 03:29 AM.

-

-

03-02-2017, 11:55 AM #7825

Thanks Tom, you guys here are so awesome! I am so lucky to have found this place and made such great friends.

Your help is appreciated more than I can sayLook sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

-

03-02-2017, 04:02 PM #7826Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

I have managed to get a nice satin finish on new horn. The thing I have never been able to replicate is the look of old horn. I manage patina on steel just fine, but the technique to make horn look that way eludes me. When dealing with old horn my current thought is to get them clean, filled if needed and hydrated.

It's not what you know, it's who you take fishing!

-

03-02-2017, 04:11 PM #7827

My answer to a "old" finish on horn is using powdered pumice and applied, rubbed, with a dampened finger tip. It breaks down into finer particles as it is used. It gives a softer polish than modern polishes. From my renewing , it appears that many of the old scales were hot pressed and do not de laminate like some recent renewal scales available on line. YMMV~Richard

-

-

03-02-2017, 04:11 PM #7828

It is doable. The last one I did a long while back turned up pretty nice. http://straightrazorpalace.com/custo...d-marsden.html

So many more are still waiting!

-

-

03-02-2017, 10:12 PM #7829

I can put a patina on steel very easily and quickly but at the rate my horn is going it will take and estimated 100 years for me to do it.....

-

03-03-2017, 12:31 AM #7830Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26

That horn really came out nice!

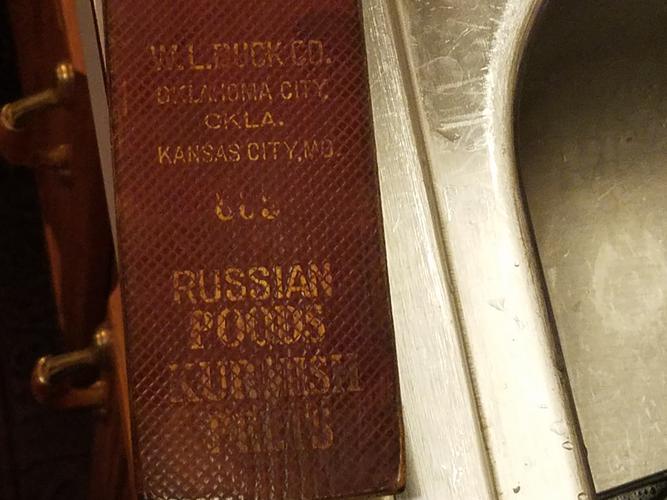

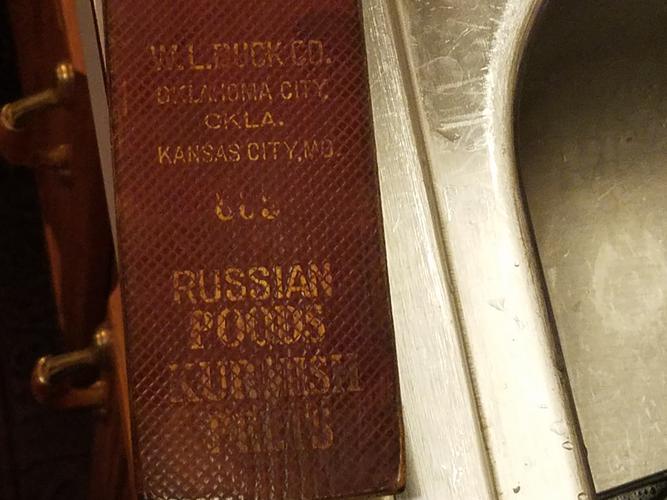

I need some help with this strop I just acquired.

Its a WL Buck company. Russian tanned 885. The side in the pic was on the inside. I have not seen a textured strop before. The side exposed said belt driven on the top. Any info on this before I clean it up?

Last edited by Cheferik; 03-03-2017 at 12:35 AM.

91475Likes

91475Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote