Results 581 to 590 of 3708

Thread: Hone of the Day

-

03-01-2016, 08:59 PM #581Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Looks great Steve, nice job!

-

The Following User Says Thank You to eKretz For This Useful Post:

Steve56 (03-01-2016)

-

03-02-2016, 12:33 AM #582

If the cosmetics of large bevels is of concern, use tape. Japanese tools,tho, wa-kamisori included, are all intended to be used right down to a stub so even with a lot of hone wear they may shave quite well with restoration. I did a few Iwasaki's recently that were so worn I would have rejected them if from any other maker but even with the resultant large bevels they shaved as only an Iwasaki tamahagane razor can.

Needless to say, it's crucial to keep the pressure on the edge & the knife & tool technique of using fingertip pressure on the edge will help if used correctly.“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

-

03-02-2016, 01:12 AM #583Member

- Join Date

- Feb 2016

- Location

- North Carolina USA

- Posts

- 69

Thanked: 9

One rough old W&B but hey, it shaves well now. Started with a pretty big chip in the blade and I am just learning to hone so I'm proud of the results.

Have a great day!

Have a great day!

Craig

-

03-02-2016, 12:08 PM #584

Needless to say, it's crucial to keep the pressure on the edge & the knife & tool technique of using fingertip pressure on the edge will help if used correctly.[/QUOTE]

See starting out, and just reading, I cannot express in greater degree of importance the amount of pressure mentioned here. My wide bevels are a result of not heeding this crucial information. Thank goodness for this post and Glenns mention of torque, as opposed to just pressure alone.Your only as good as your last hone job.

-

03-02-2016, 12:31 PM #585

-

03-03-2016, 03:10 AM #586

When discussing pressure while honing, for myself, the internet is a hard medium to pass knowledge on. When reading I hear about using "light" pressure so then I use what I consider light. When I have met people that I consider knowledgeable and see them in person I think what they use is at the least medium light to medium pressure if not more.

I am not complaining or wanting to start a disagreement and think that to light is better. It is just that I think that this is a very personal thing and hard to convey in writing.

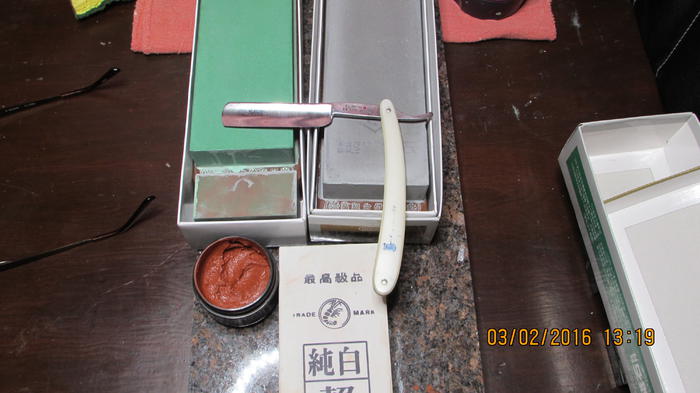

Back to the hone of the day. Here is my latest. On each side of the strop is a man made hone. reminds me of a barber hone or one found in a Rolls Razor. Thin. They seem very course after lapping using my pocket knife as a test. I think that I may have removed to much of the matrix and expose very course abrasive. I have thought about starting another thread with these questions!

The after pictures are first.

-

03-03-2016, 03:16 AM #587

No disagreement at all. I learn so much from meets. Back in the day it was called an apprenticeship. Pressure is like trying to convey a smidge, skoosh, thundercrush. Scratches up the blade past the bevel are a sign of too much pressure, Dont ask me how I know.

Your only as good as your last hone job.

-

03-03-2016, 03:31 AM #588

Filly Cmon, Chosera 1,5K Snow White, met a little FeOx. No micro-chipping. Feel like I cheated on my naturals.

Your only as good as your last hone job.

Your only as good as your last hone job.

-

03-03-2016, 02:55 PM #589At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,976

- Blog Entries

- 1

Thanked: 13229

Something that helped define pressure, I learned by teaching at the Meets, might help here also, I have said it before but maybe some haven't read it...

The Bevel and the Razor can determine the pressure needed

When you push the razor down the hone watch the ripple of water/slurry at the front of the edge, that little wave of water determines the pressure, it really does..

If that wave disappears under the edge you are no longer honing the edge, you are honing behind it and doing nothing good apply more pressure and torque..

If the wave is in front of the edge you are running fine..

Now comes the cool part, as the very front of the edge gets Thinner (Sharper) the water will start to ride up on the blade face (Undercutting) if you lighten up on the pressure the wave will move back down toward the front of the edge...

Try and ride that wave and keep it at the front of the edge and it will automatically adjust the pressure for you

I know, I know, sounds way too simple doesn't...

Torque is also a factor here that needs to be addressed, it is hardly ever mentioned except by me and Randydance, we talk about it at the meets and even can show you the little dents in our thumbs and fingers that form from applying torque when honing..

Basically it is a learned skill but you do want to be torquing the razor as you are honing toward the edge, just how much torque, you have to learn, but again watch the wave it will help you adjust..

Hope that helps somebodyLast edited by gssixgun; 03-03-2016 at 03:02 PM.

-

The Following 8 Users Say Thank You to gssixgun For This Useful Post:

32t (03-03-2016), CZMark (03-04-2016), dinnermint (03-03-2016), Geezer (03-03-2016), markbignosekelly (03-03-2016), MikeB52 (03-03-2016), ultrasoundguy2003 (03-03-2016), yotebuster1200 (03-08-2016)

-

03-03-2016, 03:04 PM #590

Be yourself; everyone else is already taken.

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

32t (03-03-2016)

23368Likes

23368Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote