Results 17,111 to 17,120 of 20573

Thread: What are you working on?

-

09-16-2019, 02:08 PM #17111Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“Does anyone have any advice on how to proceed with this? I want to re-scale this microtome / section cutter type blade.”

While I don’t have a microtome handy to look at, I’m pretty sure they are scaled and pinned just like a normal razor.

It’s the tang you have to clear, and the tang should be the same on both sides, how the blade is ground does not matter.

If you make a proper wedge with the narrow side about half the width of the thick side, it should keep the pivot open by about a Ĺ -3/4 inch, (before pinning) more than enough clearance for the tang. The blade should close centered if the holes are drilled straight and pinned properly. While the tip may not be centered it should clear the scales easily, if the scales have enough flex. Most old Microtomes I have seen were scaled in Horn or Gutta percha, (hard rubber)

With the scales bolted up on the pin, place the blade in the scales where you want it to sit when closed, (so the edge is not poking out the bottom). Mark the top of the scale on the blade, where it sticks out of the top of the scales. Measure the width of the tip at the mark and make the thick side of the wedge, that width. When pinned closed, that is where the blade will contact the scales and stop.

You can make a set of micro bolts, by running 2-3 nuts to the head and putting a drop of CA glue on them. If you don’t have “Micro Bolts”, you can pick up a pair of 1/16 bolts or screws at most good hardware or electronics stores.

Test fitting will save you a lot of headaches.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

Montgomery (09-16-2019), ScoutHikerDad (09-17-2019)

-

09-16-2019, 10:09 PM #17112Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

Many thanks for the input.

I made three sets of scales of this size together, as I had three razors of the same size. This is the last of the three, the first two are great, and the microtome blade is causing the headache. I pinned the scales with a wedge and mocked the whole thing up, and with conventional scale geometry, it is a long way from working. I will endeavour to explain.

The issue is that on the reverse side of the blade, the tang, face of the blade, spine edge and edge are all essentially in the same plane. That means that if you lie the reverse of the blade on a flat surface, it essentially lies flat, tang, blade, edge, spine and all. So, it is not simply a matter of different grinds on each side of the blade. (One way of visualising it would be to imagine a typical blade, bisected lengthways top to bottom, ending up with two pieces, both of which have the same profile as the original razor, but have one completely flat side, and one side where the blade retains its grind, its tang angle, etc).

I will illustrate with pictures:

First, the front side of the blade; as you can see, with the front of the blade on the table, pushing down on the tang, the angle between the tang and the blade plus the fact that this side is ground hollow means that with the tang flat on the table, the edge at the point is a good 6mm from the table.

Now, the reverse side of the blade; lying the blade flat and pushing down on the tang at the pivot, the blade lies almost completely flat, with the tang, most of the edge, the flat of the blade and the spine in more or less the same plane and all in contact with the table (to within 1mm or so).

So far so good.

At this point, it is worth reflecting on how a razor usually fits into its scales. The edge of the razor rotates around the pivot in an arc which passes between the scales. The spine edges rotate in different arcs. The gap between the scales is smaller than the width of the spine, so the arcs that the spine edges rotate in do not pass between the scales, which means that the blade comes to rest at the point where the blade/spine thickness exceeds the gap between the scales.

Continuing to visualise what would happen with a blade where the tang, face of the blade, spine edge and edge are all in the same plane and thus rotating in the same arc, it is clear that if the edge clears the scales, so must the flat of the blade and the spine, and the converse is also true in this scenario, if the spine does not clear the scales, the edge will also not clear the scales.

This also means that the edge cannot be centred in the scales. This makes a huge difference, and of course, makes scaling very problematic.

I will illustrate again with pictures:

Here is a rough mockup, with a rivet through the pivot holes, pinching the scales onto the tang on both sides. Remember, on the left side of the blade as you look at the picture, the tang, spine, blade and edge are in almost the same plane.

Following on from this, the next picture illustrates the problem best of all.

The fact that on the reverse of the blade, the tang, flat of the blade, spine edge and edge are all in the same plane and rotate in the same arc around the pivot means that the edge does not centre in the scales, and that unless the scale on that side is pretty much perfectly straight, the edge will bind on the scale. I think this picture shows this very clearly.

So, it is obvious that if we pull the scales together conventionally with a wedge, the edge with bind on the scales.

Does that make the problem clear? This is the only microtome I have seen, and so I suppose it is quite possible that the only difference with most microtomes and a standard razor is the different grind on the two sides of the blade. As you have seen, that isn't the case with this one.

Anyone have any ideas? The only solution I can currently visualise is one where the reverse scale is straight or almost straight, so as not to bind on the edge, and the front scale is curved as usual or slightly more so. This might be possible by using scales of different flexibilities and slightly different lengths. I am not totally happy with this solution, but will try it in the absence of any other ideas.

Many thanks!

-

09-16-2019, 10:41 PM #17113Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228

Have you considered that a bent tang may be causing the trouble?

BobLife is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

Montgomery (09-16-2019)

-

09-16-2019, 10:43 PM #17114

-

09-16-2019, 10:47 PM #17115Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228

Here are some ideas on bent tangs from the forum's library https://shavelibrary.com/w/Blade_Centering .

Also type in "bent tang" in the forum search box upper right of the page. That will bring up a number of threads on the subject.

BobLife is a terminal illness in the end

-

The Following 2 Users Say Thank You to BobH For This Useful Post:

cudarunner (09-16-2019), Montgomery (09-16-2019)

-

09-16-2019, 11:05 PM #17116Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

Not really, but I don't know much about bent tangs. I have had razors with uneven tangs before, but that explanation doesn't ring true. It would be very hard to bend a piece so that it looked so much like it was meant to be made that way, and was almost dead flat.

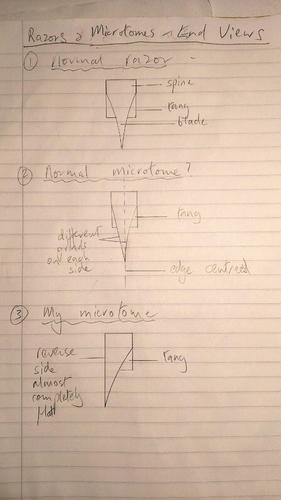

Remember, on the reverse of the blade, the tang, the blade, the edge and and the spine edge are all pretty much in the same plane. If you can visualise that, you will see the problem. I realise words don't always get the message across, so did a quick sketch to show what is going on:

Now imagine how you would put scales on number three, and tell me the answer

It all looks precise enough to indicate that it was made that way, I can't see anything to indicate that it has been messed about with.

Edit: I checked the link, and see that 'bent tang' just means an off-centre tang, not one that has been bent after manufacture.Last edited by Montgomery; 09-16-2019 at 11:13 PM.

-

09-16-2019, 11:13 PM #17117Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,454

Thanked: 4830

Your front scale needs to be a teeny tiny bit longer than the back scale. Put you blade in, pinch the wedge in place and flex the front scale over. That should give you the clearance on the back side. It does not take much.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Montgomery (09-16-2019)

-

09-16-2019, 11:24 PM #17118Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228 Life is a terminal illness in the end

Life is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

Montgomery (09-16-2019)

-

09-16-2019, 11:24 PM #17119Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

-

09-16-2019, 11:29 PM #17120Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

I get that. I want to avoid changing the shape of the steel if I can avoid it, and until I am sure it wasn't meant to be like that originally.

I will mess about with some bits of plastic and see if I can get the right balance of curves to make it work.

It's academic anyway, I have no desire to shave with this blade, just an interesting exercise and learning experience. I do have a blade which I do want to shave with and which does have a very bent tang, so what I learn will be useful, so thanks for the bent tang wiki link.

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote