Results 1,621 to 1,630 of 4688

Thread: The Butchered Blade

-

10-08-2015, 08:03 PM #1621

If it was mine, and the hole of that squarish type, I'd just tap some copper, brass, bronze or whatever with a different color to pin it and polish it flat to preserve the contour. Probably just the same if round.

Hey, sharptoon, have you an old gold ring you will not use anymore? Would be a great source of metal to fill the hole. Ex-wives souvenirs are good to make things like this.

-

10-08-2015, 08:12 PM #1622

I don't belong here but I like lurking, wanting to be around the cool kids. All I do is maintain my razors...this includes the occasional pin tightening.

Looking at the beautiful anvil that outback fashioned from a piece of rail track...I felt a little inadequate with my little bench anvil...no actual bench for me as I live in an apartment. Everything has to be small here. I started thinking about my use of the anvil and I came up with this: when pin tightening I only use a small (pin size ) part of the anvil. So I started thinking, what else could I use for an anvil?

) part of the anvil. So I started thinking, what else could I use for an anvil?

Here is what I came up with...can't say I made it which is why I don't belong here. But what the heck. The ball bearing is G25 grade, 0.000025" round. I eyeballed it and I think they are right. Had to look for an appropriate base which was the base for a pot (turned upside down), which holds the pitch that engravers use. Now, I wonder if it will work...so far so good. The sphere is 3" in diameter.

"Call me Ishmael"

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

-

10-08-2015, 08:18 PM #1623

Great kludge, WW243! Three inches, that's a big BB! And welcome to the most classy derailed thread of the SRP. Hard to guess by its name, but with a lot of great treasures spilled all over the embankment.

Nice luthier hammer you have!Last edited by Matheus; 10-08-2015 at 08:23 PM.

-

10-08-2015, 08:50 PM #1624

Nice ball-bearing anvil, Bill!

No ex-wife gold around, Matheus!

No ex-wife gold around, Matheus!  I figure as I will thin the tang down, I had better just weld-up the hole!

I figure as I will thin the tang down, I had better just weld-up the hole!

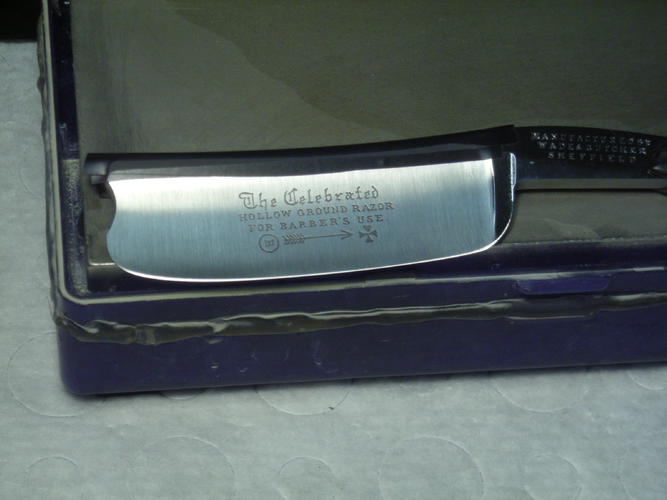

So, on another note, MikeT's razor was pretty much breadboarded, so a few layers of tape, swooping on a worn DMT, it came up super pocketknife sharp all along the edge after a bit of work. Looky at that bevel! Going to dull it a bit on a glass bottle and bring it back with one layer.

Going to dull it a bit on a glass bottle and bring it back with one layer.

I shall destroy a 5 day beard with it to-morrow morning!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

MikeT (10-08-2015)

-

10-08-2015, 09:32 PM #1625

My service is good, fast and cheap. Select any two and discount the third.

My service is good, fast and cheap. Select any two and discount the third.

-

-

10-08-2015, 09:39 PM #1626

I have a ball bearing about that size & never even thought about it but it's in my large Snap on toolbox & I don't go in there unless I'm needing a tool or working on a Harley. Great idea!!!!

@Shaun

That's what I use for drilling pivot holes, carbide drill bits. You have to have it going at a high speed or it will break the bit since carbide is hard yet brittle. I guess you can go slower but I found that when I went slower, the bit would grab & snap. When i go faster, it goes through like drilling butter. I have 1/16", 3/32" & 1/8" carbide drill bits.Last edited by engine46; 10-08-2015 at 09:43 PM.

-

10-08-2015, 09:39 PM #1627Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,406

Thanked: 4824

@UKRob

You really did cut that down. It is so small that I would be worried about it being too fragile! Clever fix though.It's not what you know, it's who you take fishing!

-

10-08-2015, 09:47 PM #1628

-

10-08-2015, 09:50 PM #1629

Ha, ha...............that's funny Shaun!!!!!

Some pivot holes are so out of round I have to use a small rat tail file to make them as round as I can get them & sometimes get lucky going lower speeds. On others I get my drill going high speed & hit the hole & it goes through. I hate twist drills when they break but I do have a friend that can sharpen them because I used to work there. I have some straight flute carbide bits that if the end breaks off, no big deal, they still work.Last edited by engine46; 10-08-2015 at 09:58 PM.

-

10-08-2015, 09:58 PM #1630

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote