Results 1,401 to 1,410 of 20573

Thread: What are you working on?

-

08-29-2015, 08:52 PM #1401

Mike, it's kind of like this but the ones I use get chucked into my cordless drill. I don't see why this couldn't be used either on the disk grinder like here or on a bench grinder.SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

The Following User Says Thank You to guitstik For This Useful Post:

MikeT (08-29-2015)

-

08-29-2015, 09:04 PM #1402Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

have you actually used those things on razors?

CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

Geezer (08-30-2015)

-

08-29-2015, 09:25 PM #1403

I'm wondering the same. I've seen those before, never thought to..

They work?

-

08-29-2015, 09:55 PM #1404Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

The Following User Says Thank You to pixelfixed For This Useful Post:

MikeT (08-29-2015)

-

08-29-2015, 10:48 PM #1405

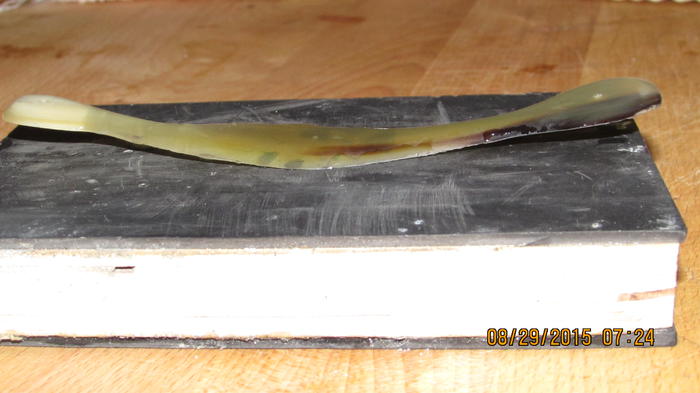

So I got some horn that is refusing to Cooperate.

Lets see how a night in the freezer works. 2 times heated with hairdryer clamped and frozen.

1 time boiled clamped and frozen.

Now boiled and twisted and over corrected freeze again.Your only as good as your last hone job.

-

The Following User Says Thank You to ultrasoundguy2003 For This Useful Post:

MikeT (08-29-2015)

-

08-29-2015, 11:13 PM #1406

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

08-29-2015, 11:23 PM #1407

Ducks without beaks, One more down.

Your only as good as your last hone job.

Your only as good as your last hone job.

-

08-29-2015, 11:26 PM #1408

That warping is the only reason I've been a bit apprehensive about creating horn scales.

Good luck! The others look great!“You must unlearn what you have learned.”

– Yoda

-

08-29-2015, 11:29 PM #1409

I don't know about those particular ones, I use the smaller version that fits in a drill. Most hand drills are variable speed and can be sped up or slowed down depending on the need of the moment. I have had no problems doing it this way. I use finer grit paper by hand as I progress to take out the deeper lower grit marks.

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

08-29-2015, 11:55 PM #1410

Lads just a note on the flap disks, we use these a lot at work for finishing steel jobs, No way in hell would I go anywhere near a razor with a flap disk on a grinder These are usually 60 - 180 grit with high a speed grinder = no more razor real quickThe burr type flap discs used in a drill or rotary burr are also fairly aggressive DIY to low grit ratings 60-180 usually also I very worn out one on low speed in a drill may work but would be only on a heavy blade with heavy damage Also both are flexible when used and don't hold a perminent shape Hope this helps Cheers D

Last edited by Substance; 08-30-2015 at 04:51 AM.

Saved,

to shave another day.

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote