Results 1,051 to 1,060 of 4688

Thread: The Butchered Blade

-

09-22-2015, 04:42 PM #1051

-

09-22-2015, 04:45 PM #1052

Darl (Tarkus) made a big punch, slash-cut on the bottom. He says it works well for smacking a square of lead on a flat steel surface to make tapered wedges.

I had thought about using a hydraulic press. Seems it could be controlled somewhat using stops or a die.

Rob has a cool setup to make wedges, I have seen it before. I think it was posted earlier on in this thread. Perhaps he will elaborate?Last edited by sharptonn; 09-22-2015 at 04:49 PM.

"Don't be stubborn. You are missing out."

I rest my case.

-

09-22-2015, 05:22 PM #1053

Yep, he does & I was the one who posted it after searching. I like it myself although there are several different ways to make one. I have used the hammer method on pieces of lead that worked out just fine. I was experimenting around the other day & thought I would try to make one flat so I got my brass piece & drilled my hole first at as close to a 90 degree angle I could. I then used a DMT diamond hone & applied pressure only on one side of it more. It seems to work out pretty good. I did it on both side since I first drilled my hole when perfectly flat. It was just an idea that popped up in my head but this was one idea of making one flat. Sandpaper on a piece of glass is pretty much the same thing or very similar. I have also done like Tom & just used my eyes to do it. MikeT seems to have the right idea of how to determine the angle of the edge.

I know I already posted this pic so I deleted it. You can see it in post 973.Last edited by engine46; 09-22-2015 at 10:06 PM.

-

The Following User Says Thank You to engine46 For This Useful Post:

MikeT (09-22-2015)

-

09-22-2015, 06:13 PM #1054

Last edited by JOB15; 09-22-2015 at 06:15 PM.

-

The Following User Says Thank You to JOB15 For This Useful Post:

MikeT (09-22-2015)

-

09-22-2015, 06:17 PM #1055

Thank you for bringing this up.

When I first joined I posted this same topic about wedge hole angle and though I explained well, it took me multiple posts to finally get someone to understand what I was talking about and grudgingly admit some merit BUT that drilling the hole bigger fixes the problem.

I admit that I do drill the hole bigger sometimes with a pin vise to not bother, but it's not ideal.

I also use a shim to drill the hole correct after the wedge taper is complete. That is a step in the process that is necessary otherwise the angle of the hole changes with sanding.

-

09-22-2015, 06:48 PM #1056Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207 "Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

09-22-2015, 09:20 PM #1057

I try and keep the pin hole quite snug on the wedge - the reason being that with some material that don't flex very well, the extra effort required to make sure the scales are flush against the sides of the wedge can force it back slightly if there's some play in the pin hole. This happened to me when I'd shaped the wedge with the blade mocked up with hex pins - when I did final fitting the finished wedge was short of the scales.

You know that feeling when you're not 100% satisfied - so I started with another wedge which meant unpinning etc.etc.My service is good, fast and cheap. Select any two and discount the third.

-

09-22-2015, 09:41 PM #1058

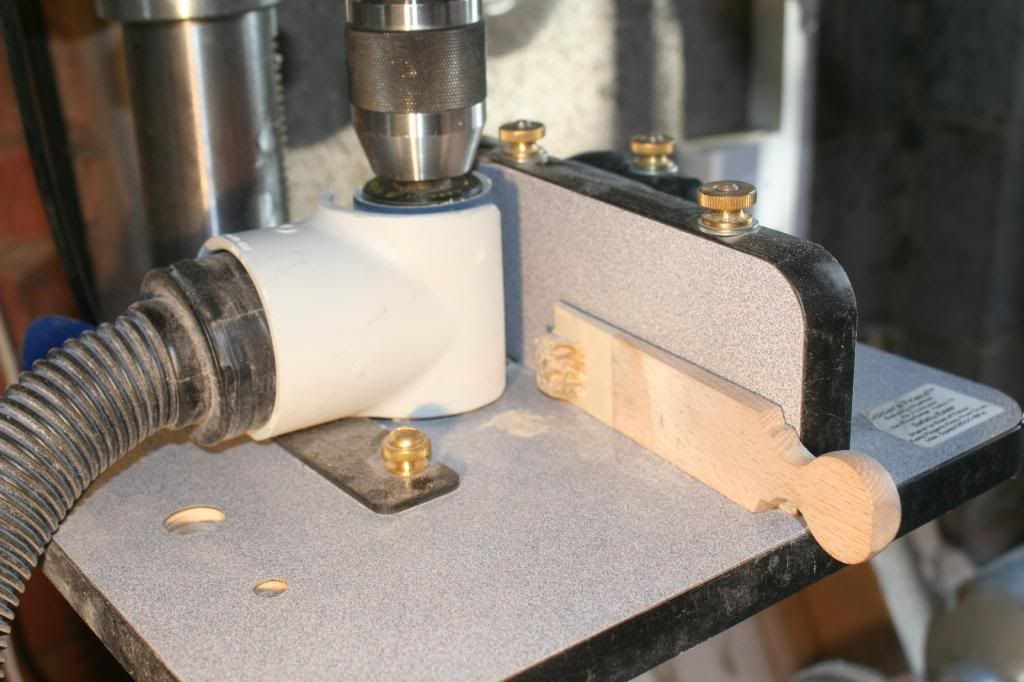

Thanks Tom. I use this Luthier's friend and door wedges depending on the angle I want - here's a couple of pictures showing the set up first and then more detail. Whichever door wedge I used for the razor wedge I then use in the pillar drill to make sure the pin hole runs at 90 degrees through the wedge.

My service is good, fast and cheap. Select any two and discount the third.

My service is good, fast and cheap. Select any two and discount the third.

-

-

09-22-2015, 09:59 PM #1059

That looks to be a very handy attachment, Rob. It seemingly would be the real deal for making wedge ends on 'wedgeless' scales?

"Don't be stubborn. You are missing out."

I rest my case.

-

09-22-2015, 10:08 PM #1060

Last edited by engine46; 09-23-2015 at 03:52 AM.

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote